Cargo Handling System Installation for FedEx at EMA

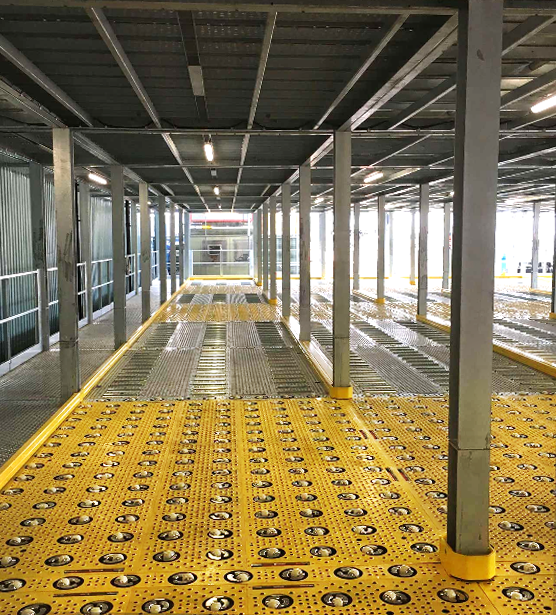

Delivering on a contract awarded in May 2024, we’ve implemented a new Cargo Handling System for FedEx at East Midlands Airport (EMA). In partnership with SACO Airport Equipment, this solution is designed to significantly improve the efficiency and reliability of their cargo operations.

Read the full story